Intake valve carbon clean

We carry out Intake valve carbon cleans on TFSI & TSI engines frequently due to build up within the valves. 90% of EU cars being manufactured now use Direct Injection to power the engine. There are so many benefits to manufacturers using Direct Injection, mainly fuel efficiency and power! The EU have more stringent emissions laws than the rest of the world, therefore manufacturers are using this method to push the limits of emission friendly cars to their max potential.

What is Direct Injection?

Most of us get into our cars and it gets us from A-B, and when something goes wrong, we take our car to the garage and trust our mechanic to fix the problem! However, in most cases its beneficial to learn why problems occur and how to stop more problems developing. Direct injection is where the fuel is injected from the HPFP to the injectors and into the combustion chamber. The ECU tells the injectors what intervals to spray the fuel in, at a precise time and position to atomise with the compressed air. This mixture then ignites and turns chemical energy into mechanical energy. At the end of the cycle, the exhaust valves open and release the excess gasses.

So, what are the draw backs?

Unfortunately, Direct injection vehicles are prone to carbon build up, HPFP failure and PCV failure. The PCV valve takes the oil vapours and recycles it into the air intake to give a more environmental burn. However, this is where the mixture can partially end up back into the intake valves resulting in the carbon built up. Sadly, it’s not a 5 minute job to check how built up the valves are with carbon. Therefore, we need to know the warning signs! The build-up of carbon essentially restricts the air flow and stops the vehicle being able to breathe. Signs you need an intake carbon clean include; Noticeable loss in performance, Check engine light on/won’t pass emissions, Poor fuel economy and Rough running. If you’re experiencing these problem and the vehicle has hit the 30,000 miles mark we would advise an intake valve clean. After that first clean, it shouldn’t need carrying out again until 40-50,000 mile intervals.

What method do we choose to clean?

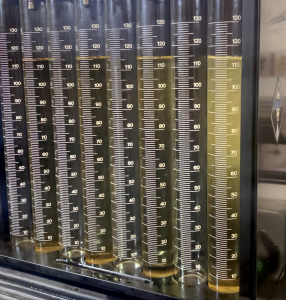

There are a number of ways to clean your intake valves however we prefer methods that don’t damage the valves. If you choosing to manually scrape off the carbon built up your going to scratch the metal which could cause more problems. We choose to use walnut shell. It is soft enough to do no damage, but blasted into the valves at high pressure it removes the carbon built up safely. After your intake valve clean you should immediately see the benefits. These should include, smoother idle, lower fuel consumption and smoother throttle response.

We also advise having your injectors tested and cleaned at the same time as your intake valve clean. You can read our blog outlining the benefits of this ‘here’.

To book in or get a quote call us on 01642 613852. Use our contact form ‘here’ on contact us on Facebook.